Appearance & Measurement Experts since 1986

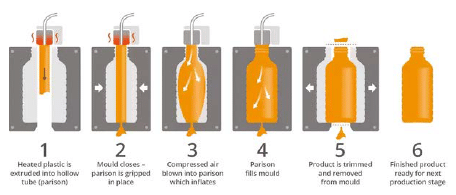

To ensure consistent quality of the finished product, the accurate control of operating parameters must be ensured. Should problems occur it is essential they are identified quickly to prevent wastage.

Typical problems can include:

Using the Rhopoint ID it is possible to identify these problems in order to correct in process

failures.

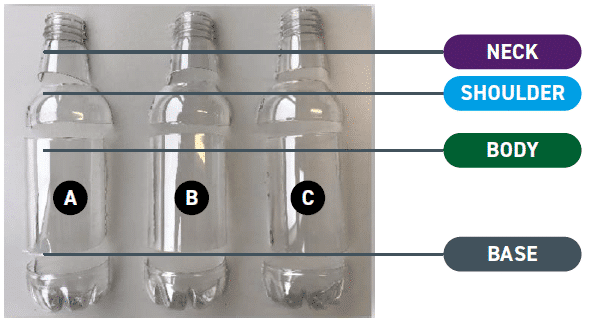

STEP 1: Three different customer supplied PET bottle samples were tested. Visually, they were all considered to be low haze with a “water white” appearance. Each bottle (A,B and C) was cut into 4 sections, labelled: Neck | Shoulder | Body | Base for measurement on the Rhopoint ID-L.

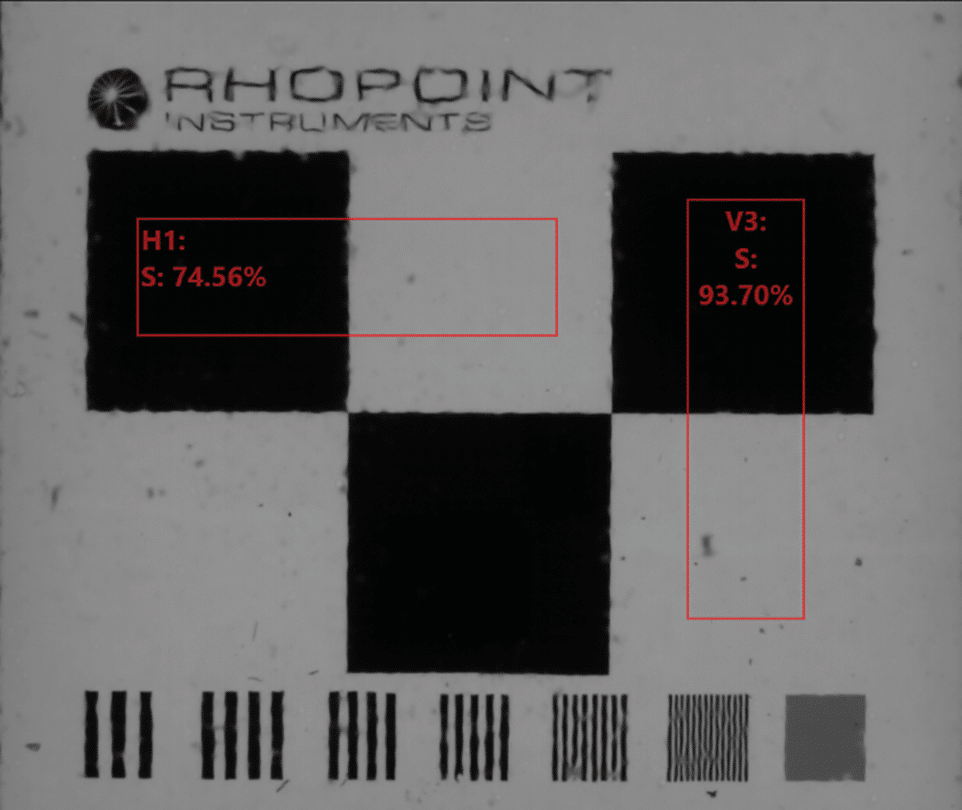

On closer inspection, the parts from bottle C were visually grainy, generally lower in sharpness and contained visible lines in the material that suggested anisotropy.

STEP 2: As the Rhopoint ID is vertically oriented, sample mounting was very easy, no adaptor or sample holding device was required. The cut samples were simply positioned onto the graticule and a measurement made.

Example – PET Water Bottles

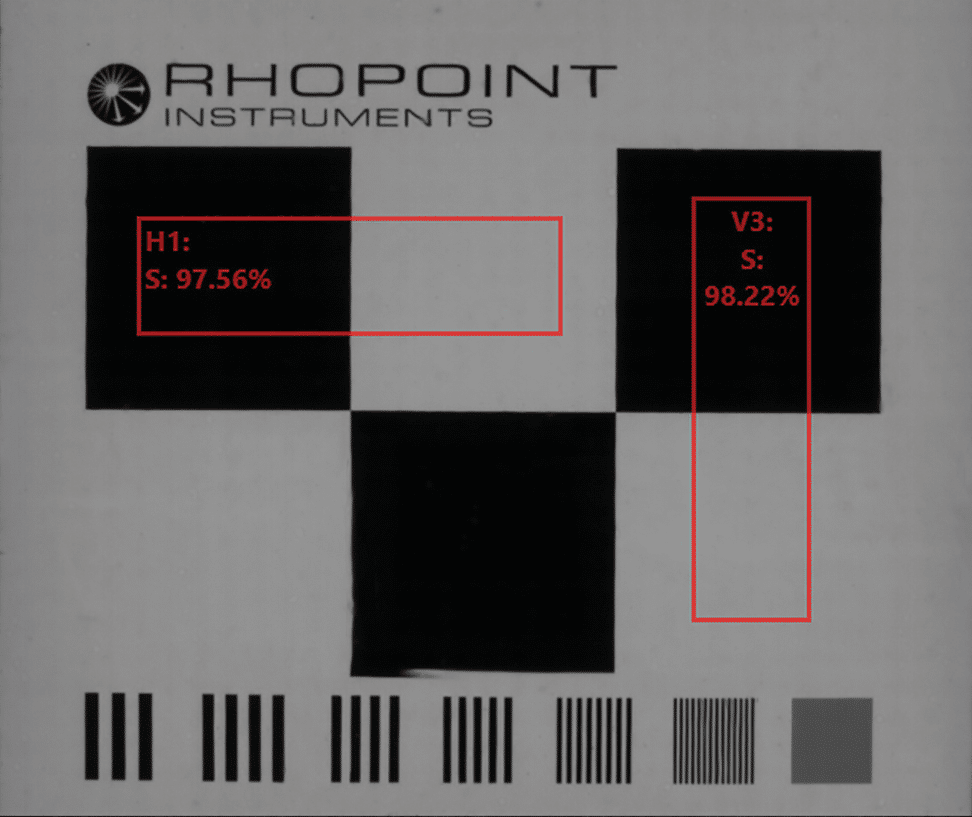

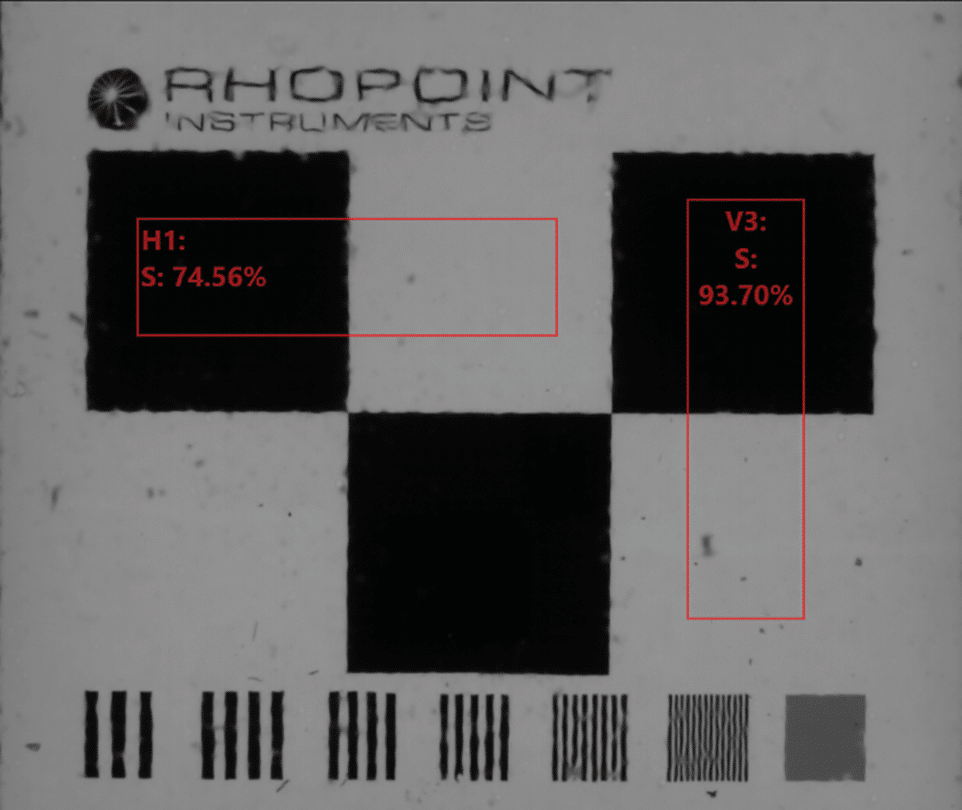

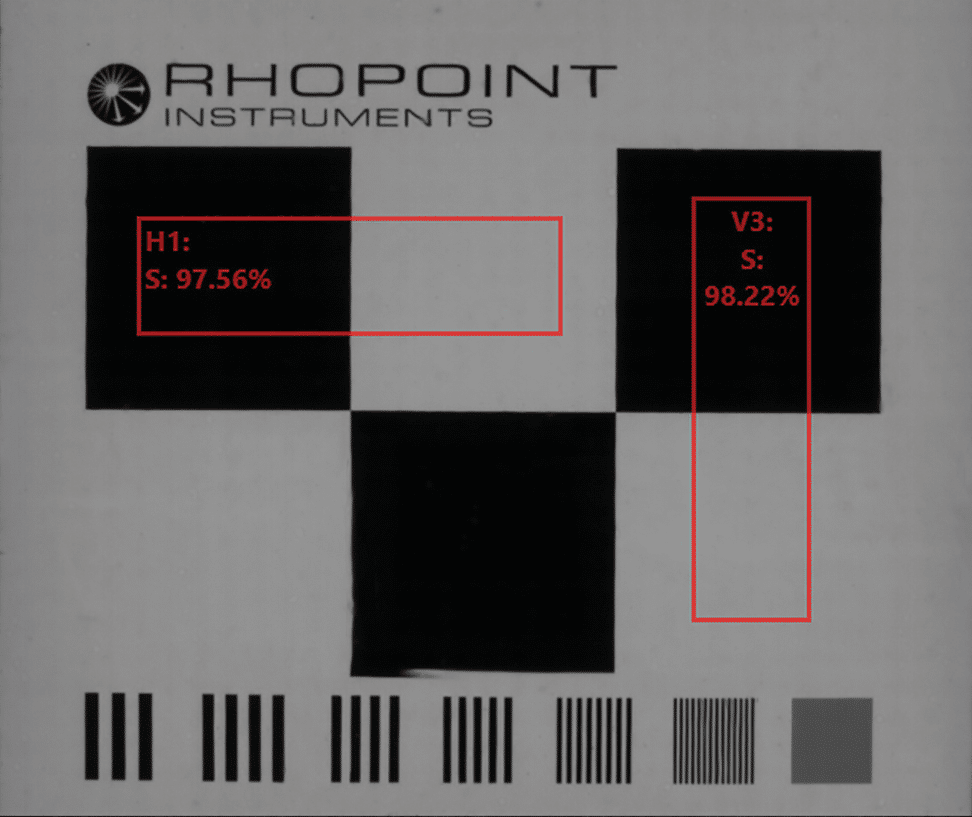

The images and data that follow was taken directly from the Rhopoint ID. Being a camera-based system it has the unique ability to provide detailed images of the measured sample that are very useful to verify problems in the quality of the material.

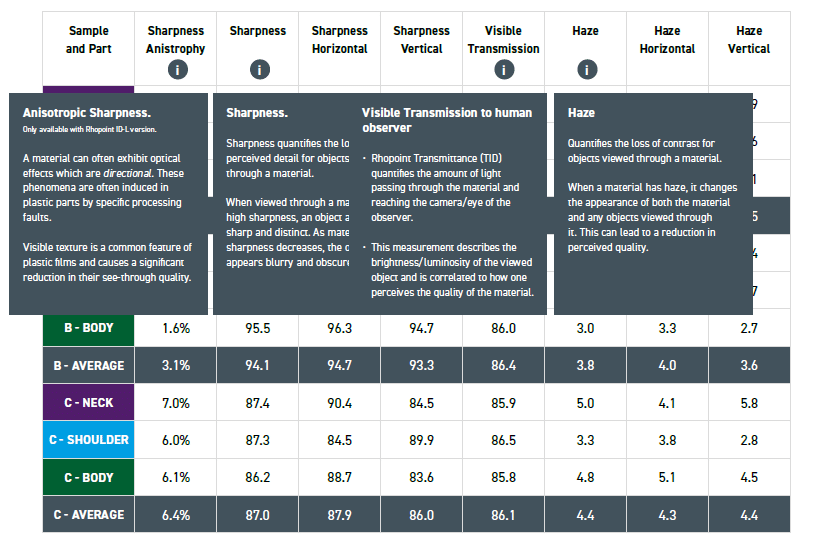

Measurement analysis Bottle B

B-Shoulder – best quality

| Sample and Part | Sharpness Anisotropy | Sharpness | Sharpness Horizontal | Sharpness Vertical | Visible Transmission | Haze | Haze Horizontal | Haze Vertical |

|---|---|---|---|---|---|---|---|---|

| B - SHOULDER | 2.2% | 94.9 | 93.5 | 95.6 | 87.0 | 3.1 | 3.6 | 2.7 |

Measurement analysis Bottle C

B-Shoulder – best quality

| Sample and Part | Sharpness Anisotropy | Sharpness | Sharpness Horizontal | Sharpness Vertical | Visible Transmission | Haze | Haze Horizontal | Haze Vertical |

|---|---|---|---|---|---|---|---|---|

| C - SHOULDER | 6.0% | 87.3 | 84.5 | 89.9 | 86.5 | 3.3 | 3.8 | 2.8 |