Appearance & Measurement Experts since 1986

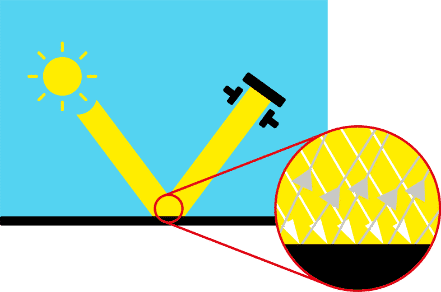

Haze is light that has been reflected by very small surface structures adjacent to the main specular angle. The term “Haze” defines the milky halo or bloom observed visually on high gloss surfaces.

Surface haze can be problematic in most coating applications including automotive manufacture, powder coatings and other high gloss coatings. It can be attributed to a number of causes including incompatible materials in a formulation, poor dispersion and problems encountered during drying/curing/stoving.

Coatings without haze can be seen to have a deep reflection and have high reflective contrast. Those with haze exhibit a slight “milky” finish which can be seen over the highly glossy surface.

Haze is caused by microscopic surface texture which diffuses light adjacent to the main component of the reflected light.

When viewing the reflection of a strong light source in a surface with high haze, the image “blooms” and has a bright halo around it.

Haze is an important measure for highly polished metals and is often associated with polishing marks and machining direction.

Using the LDA technology in the Rhopoint IQ, measurement of Haze is easily achieved, using the procedure described in ASTM E430, by analysing the amount of light that has been deflected +/-2° either side of the specular angle.

Haze compensation is also included to allow haze measurement on different coloured surfaces, the light diffusion caused by bright colours e.g. white, yellow would otherwise produce higher levels of haze even though they are the same.

This measurement is performed automatically by the instrument in one process.