Appearance & Measurement Experts since 1986

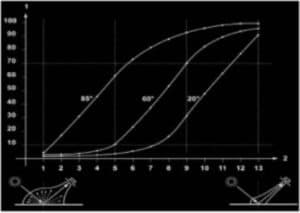

Yes, see table. 60 and 85 give greater resolution of measurement at these gloss levels (small visible differences in finish = a large difference in gloss value)

Whilst 20 has a smaller measurement resolution, visible differences in gloss can be quantified with the Flex 20.