Appearance & Measurement Experts since 1986

Waviness is an optical effect caused by large structures (0.1-2mm) on the surface of a material. If the structure is homogeneous it is often described as orange peel – the surface resembles the peel of an orange.

If the effect is anisotropic, visible lines can often be seen when looking through the material.

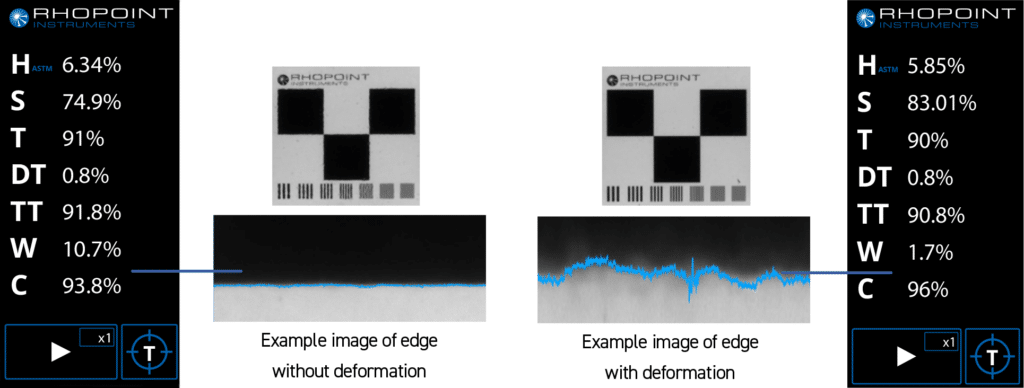

Unlike haze, these larger structures can cause dynamic distortion when the film is moved over a target image/object which has straight edges – the edges appear to distort and wave as the material is moved. To ensure consistent quality of the finished product, the accurate control of operating parameters must be ensured. Should problems occur it is essential they are identified quickly to prevent wastage.

Typical problems can include:

• Orange peel and texturing

• Mould lines or marks

• Contamination

• Haze caused by surface roughness and bulk scatter

Using the Rhopoint ID it is possible to identify these problems quickly and effectively in order to correct in-process failures.

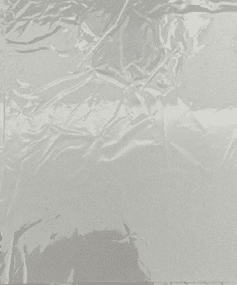

Example – BOPP film

OK

- No visible waviness present

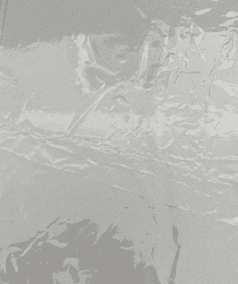

Not OK

- No visible waviness present

STEP 1: Place each film on the ASTM measurement platen and clamp using a magnetised spacer on Rhopoint ID.

STEP 2: Measure each sample once. Download results and analyse

Example – BOPP film

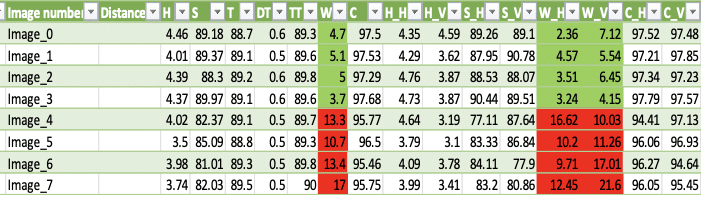

The images and data that follow were taken directly from the Rhopoint ID. Being a camera-based system it has the unique ability to provide detailed images of the measured sample that are very useful to detect problems in the quality of the material.

Waviness W is displayed in Vertical (W_V) and Horizontal (W_H) directions.

The values for waviness for the OK samples were low confirming that little or no orange peel was present on the surface.

However, for the Not OK samples the Waviness values were high confirming the presence of orange peel. Also the values for W_H and W_V were not similar indicating there were in process directionality issues in the way the orange peel was being manufactured.

The measurement results confirmed the visual evaluation of the samples. Rhopoint ID was able to distinguish between good and bad samples in terms of Orange Peel present on the surface from the Waviness values.