Appearance & Measurement Experts since 1986

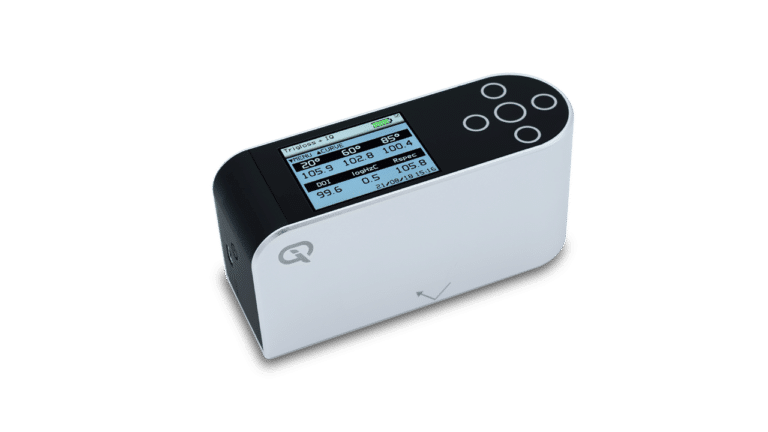

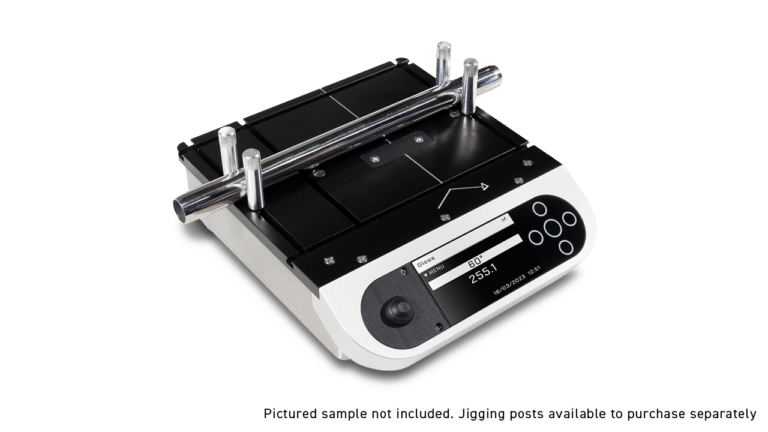

When the instrument is received, we assess the physical condition and test its basic functions. We then survey the repeatability, accuracy and linearity of the instrument using a minimum of 8 gloss standards. If any major repairs are required, you will receive a quotation at this point before any work is undertaken.

Next, the optic elements and reference gloss tile are cleaned. The glossmeter is then calibrated at a minimum of 8 points throughout the full range of measurement for each angle, with minor adjustments made if required. The reference gloss tile is assigned new values from our master standards or replaced if it is damaged, and an updated certificate is produced.

The calibration date, internal stored calibration values, calibration reference and certification for your instrument are all updated. A report of the as-received readings is also supplied, so that any changes made during the calibration can be tracked and accounted for in a fully-traceable manner.